Tank vents and hatches tools.

Vacuum breaker storage tank.

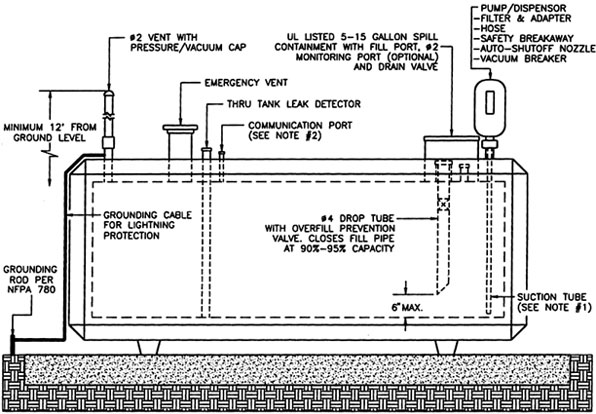

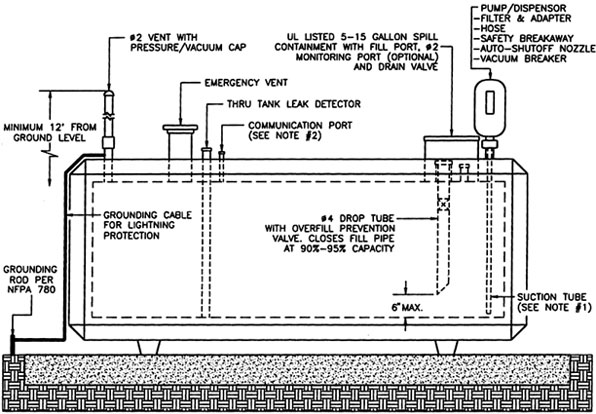

Their primary purpose is to protect a tank against rupture or implosion by allowing the tank to breathe or vent when pressure changes in the tank due to normal operations.

Also eliminates siphoning of dangerous fluids and prevents vacuum damage to sensitive instruments and filters.

Venting of aboveground storage tanks is one of the most difficult aspects of tank engineering to understand.

Series vb vbm patented diaphragm design assures dependable repetitive bubble tight sealing to protect enclosed tanks from collapse or structural damage during draining.

Spare parts minimize variability reduce costs and increase safety and production by choosing genuine oem spare parts.

Falling liquid levels and condensing steam can cause a vacuum that can damage a tank.

Proper venting of tanks and vessels is essential to conserve product reduce emissions and minimize hazards to people and equipment.

Lock down hatches provide secure access to storage tanks without pressure or vacuum relief capability.

Features iron steel or stainless steel body iron steel or stainless steel seat.

The unit must be installed vertically with its mounting connection downward.

The 200 vacuum breaker opens gradually to.

The tank s vapor space pressure vacuum works in opposition to the force weight or spring applied to the pallet assemblies.

The 200 vacuum breaker opens gradually to admit outside air to relieve the vacuum in the tank.

Once the excess pressure or vacuum condition has been relieved the pallet assemblies reseal automatically.

Typical leg actuated vent top with vacuum breaker closed left and open right venting types and.

Falling liquid levels and condensing steam can cause a vacuum that can damage a tank.

For critical applications where vacuum protection is a must or where column separation is predicated a vacuum breaker is used.

1 2 3 4 and 1 in a wide range of materials and connection types.