Most often i see this on the inside of hei distributors but it can be common on any distributor this material is iron oxide and is the result of misfires inside the cap from errant sparks inside.

Vortec distributor cap corrosion.

I replaced the coil a year ago when it went.

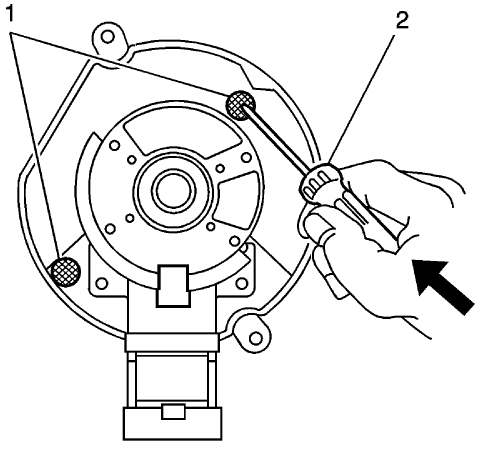

Look and see there should be one or two vent holes that have a metal screen on them.

The engine starts and runs nicely with the.

998 chevy vortec 4 3 has developed an appetite for distributor caps.

Make sure they are not stopped up.

One other thing to look at is the bottom plate of the distributor.

Vents are plugged easily and cause white brown cap dust and green black rotor issues moisture gases corrosion all directly related to poor running and the p0300 because the distributor cant vent correctly.

It recommends taking out the wire screens located somewhere on the base of the distributor.

When stopped up the inside of the cap will not breathe and it tends to suck up moisture.

But looking more closely i ve seen a dark brown material coating like this before appearing like a very fine powder.

I warm up my engines every couple of weeks and i find a layer of green corrosion on the contacts after a couple of months.

I have considered using a higher dwell module and high performance coil but i m not completely sure this.

1 the air gap between the rotor and cap electrodes is greater on the 5 7 vortec engine causing the rotor to prematurely burn.

Gm parts cost a little more but they last 3 or 4 times longer.

Presently has 235 000 miles runs great until the cap develops corrosion on the inner terminals.

I only get 1 2 years before the distributor cap gets so gunked up it misfires and has to be replaced.

I clean with contacts with a dremel brush and the green corrosion comes right off.

At first glance i thought the dark area on the cap was grease.

The a c hose above the cap deposits water on the cap as well on models with the hose routed over the cap.

I find the contacts in my distributor cap getting corroded fairly rapidly.